Sintered NdFeB makeneteke alloy magnet e entsoeng ka Nd, Fe, B le likarolo tse ling tsa tšepe. E sebelisoa haholo ho li-mini-motors, lijenereithara tsa moea, limithara, li-sensor, libui, sistimi e emisang matla a khoheli, mochini o tsamaisang motlakase le lits'ebetso tse ling tsa indasteri. Ho bonolo haholo ho corrosion libakeng tse mongobo, ka hona hoa hlokahala ho etsa kalafo ea bokaholimo ho latela litlhoko tsa bareki. Re ka fana ka liaparo tse kang Zinc, Nickel, Nickel-copper-nickel, Silver, Gold-plating, Epoxy coating, joalo-joalo Kereiti: N35-N52, N35M-48M, N33H-N44H, N30SH-N42SH, N28UH-N38UH-N38UH, N28

Mokoloko oa Sintered Neodymium Magnet Manufacturing

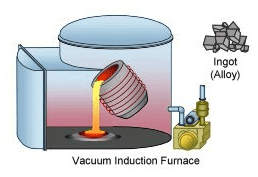

Lisebelisoa tse tala tsa makenete le litšepe tse ling li pepesetsoa maqhubu a mahareng ebe li qhibiliha ka seboping sa induction.

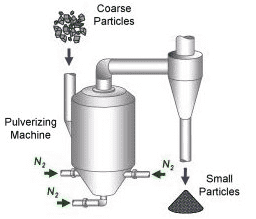

Ka mor'a ho phethoa ha mehato e fapaneng ea ts'ebetso, li-ingots li phunyeletsoa ka likaroloana tse nang le li-micron tse 'maloa ka boholo. E le ho thibela oxidation hore e se ke ea etsahala, likaroloana tse nyenyane li sirelelitsoe ke naetrojene.

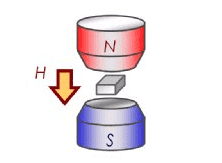

Likaroloana tsa makenete li kenngoa ka har'a jig 'me matla a khoheli a sebelisoa ha limakete li hatelloa ka libopeho haholo-holo. Kamora ho bōptjoa ha pele, ho hatella isostatic ea oli ho tla tsoela pele ho etsa libopeho.

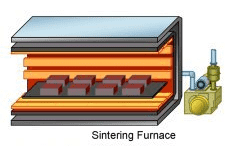

Li-magnetic particles li kenngoa ka har'a li-ingots tse hatelitsoeng 'me li tla phekoloa mocheso ka sebōping sa sintering. Boima ba li-ingots tsa pele bo fihla feela 50% ea boima ba 'nete ho sintering. Empa ka mor'a sinteing, 'nete density ke 100%. Ka ts'ebetso ena, tekanyo ea li-ingots e batla e fokotseha ka 70% -80% mme molumo oa eona o fokotsehile ka 50%.

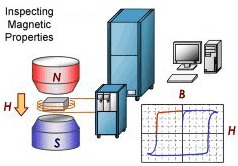

Lintho tsa motheo tsa makenete li behiloe ka mor'a hore mekhoa ea sintering le botsofali e phethoe. Litekanyo tsa mantlha tse kenyelletsang bongata ba remnant flux, coercive, le sehlahisoa sa matla se phahameng se tlalehiloe.

Ke limakete feela tse fetisitseng tlhahlobo tse romelloang lits'ebetsong tse latelang, joalo ka machining le ho kopanya.

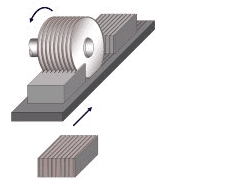

Ka lebaka la ho fokotseha ho tloha ts'ebetsong ea sintering, litekanyo tse hlokahalang li finyelloa ka ho sila li-magnets ka li-abrasives. Li-abrasives tsa daemane li sebelisoa bakeng sa ts'ebetso ena hobane makenete e thata haholo.

E le ho lumellana hantle le tikoloho eo li tla sebelisoa ho eona, limatlase li tlas'a mefuta e fapanengmekhoa ea phekolo ea holimo. Limanete tsa Nd-Fe-B hangata li ts'oaroa ke mafome ka ponahalo e ts'oaroang joalo ka NiCuNi magnet, Zn, Epoxy, Sn, Black Nickel.

Kamora ho plating, litekanyo tse amanang le tlhahlobo ea pono li tla etsoa ho netefatsa ponahalo ea sehlahisoa sa rona sa makenete. Ntle le moo, ho netefatsa ho nepahala ho phahameng, re boetse re hloka ho lekola boholo ho laola mamello.

Ha ponahalo le boholo ba mamello ea makenete li tšoaneleha, ke nako ea ho etsa tataiso ea makenete.

Kamora tlhahlobo le magnetize, limakete li se li loketse ho paka ka lebokose la pampiri, esita le pallet ea lehong ho latela litlhoko tsa bareki. Magnetic Flux e ka aroloa ka tšepe bakeng sa moea kapa nako ea ho fana ka maikutlo.

Nako ea poso: Jan-25-2021